The VESDA VLF-500 detector is a very early warning smoke detector designed to protect small, business-critical environments of less than 500 m2 (5,380 sq. ft.)

The detector works by continually drawing air into sampling holes in a pipe network. The air is filtered and passed into a detection chamber where light scattering technology detects the presence of very small amounts of smoke.

Detector status information is communicated on the detector display and via relays or optional interface cards.

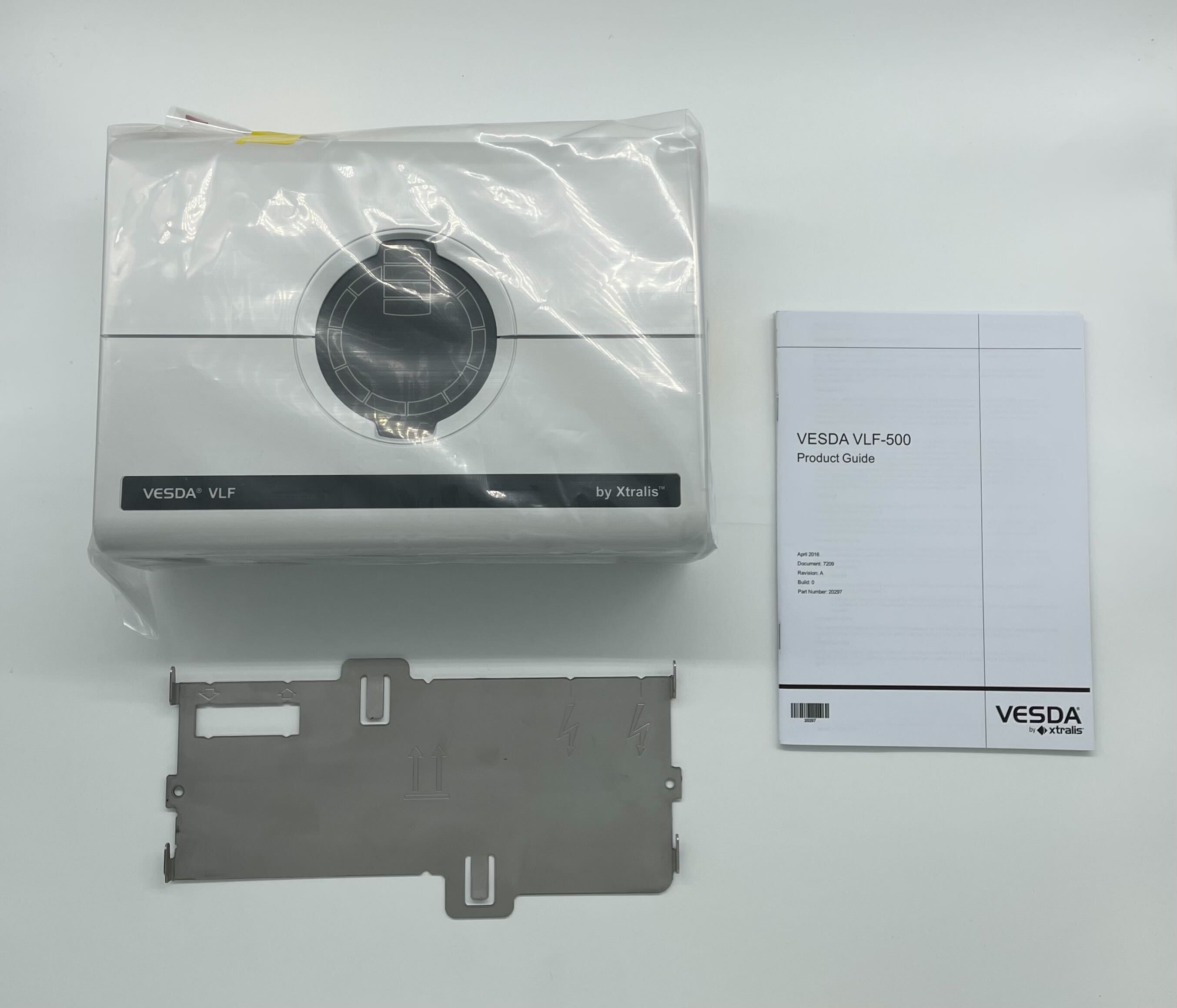

Out-of-the-Box Operation

The VLF can be installed and commissioned out-of-the-box without the need for a special interface or software programming tools. In operation, the unique Smoke DialTM display provides the user with an instant understanding of a smoke event, even from a distance. Should a fault occur, the user simply opens the field service door and activates the Instant Fault Finder feature to determine the specific fault condition. This information can then be passed onto their fire service company, ensuring that service technicians arrive onsite fully prepared.

Ultrasonic Flow Sensing

The patented Ultrasonic Flow Sensing used in the VLF provides a direct reading of the sampling pipe flow rate. The system is immune to air temperature and pressure changes and is unaffected by contamination. The VLF is the first air sampling smoke detector to use ultrasonic flow sensing.

Features

- Out-of-the-Box Installation and Commissioning

- Ultrasonic Airflow Sensing

- Laser-Based Absolute Smoke Detection

- Pre-engineered pipe network designs

- Programmable Alarm Thresholds

- Clean air barrier optics protection

- Instant Recognition Display

- Instant Fault Finder™

- AutoLearn™ Smoke

- AutoLearn™ Flow

- Field Service Access Door

- Multiple Event Logging in separate logs

- Event log – up to 18000 events

- Offline/online configuration capability

- Up to 500 m2 (5,380 sq. ft.) coverage

Listings / Approvals

- CCC

- FM Class I Div II

- ActiveFire (ISO/AS 7240-20)

- CE

- UKCA

- LPCB

- VdS

- NF

- EN 54-20

- Class A (30 holes / 0.05% obs/m)

- Class B (30 holes / 0.15% obs/m)

- Class C (30 holes / 0.32% obs/m)

Classification of any configuration is determined using ASPIRE.

Regional approvals listings and regulatory compliance vary between product models. Refer to www.xtralis.com for the latest product approvals matrix.